In an increasingly volatile global environment, supply chains are under immense pressure. From the lingering effects of the pandemic to regional instabilities and unpredictable external disruptions, companies have had to rethink the way they manage and secure their supply networks. Traditional supply chain models, built primarily around cost-efficiency and just-in-time delivery, are proving too fragile in the face of ongoing uncertainty.

The concept of a resilient supply chain has since taken center stage. This refers to a system that not only withstands disruptions but also adapts to changing conditions, recovers quickly, and sustains operations without significant compromise. In this article, we explore three practical strategies that are being widely adopted by leading enterprises to enhance supply chain resilience: diversification, digital enablement, and strategic buffering.

1. Diversification: Avoiding Single-Source Risk

Many supply chain breakdowns in recent years have stemmed from an over-reliance on one region or supplier. While centralized sourcing may offer short-term efficiency, it also makes organizations vulnerable to disruptions—be they logistical, regulatory, or environmental.

To mitigate these risks, companies are now actively diversifying across several dimensions:

Supplier Network Expansion: By engaging multiple suppliers for key components, companies reduce the chance of a complete stoppage if one vendor faces disruption.

Geographic Distribution: Establishing supply and production footprints in different regions helps avoid concentrated risk and allows for faster rerouting when issues arise.

Logistics Path Redundancy: Building out alternative shipping and delivery channels—air, sea, rail—creates flexibility and allows for continuity during transport-related delays.

For instance, manufacturers in sectors such as automotive and electronics have increasingly implemented "China plus one" sourcing models, expanding production capacity to Southeast Asia, Eastern Europe, or Latin America to complement their existing supply bases.

Additionally, cooperative arrangements like resource sharing or strategic alliances have become more common, enabling companies to stabilize labor, production, and inventory more effectively in times of constraint.

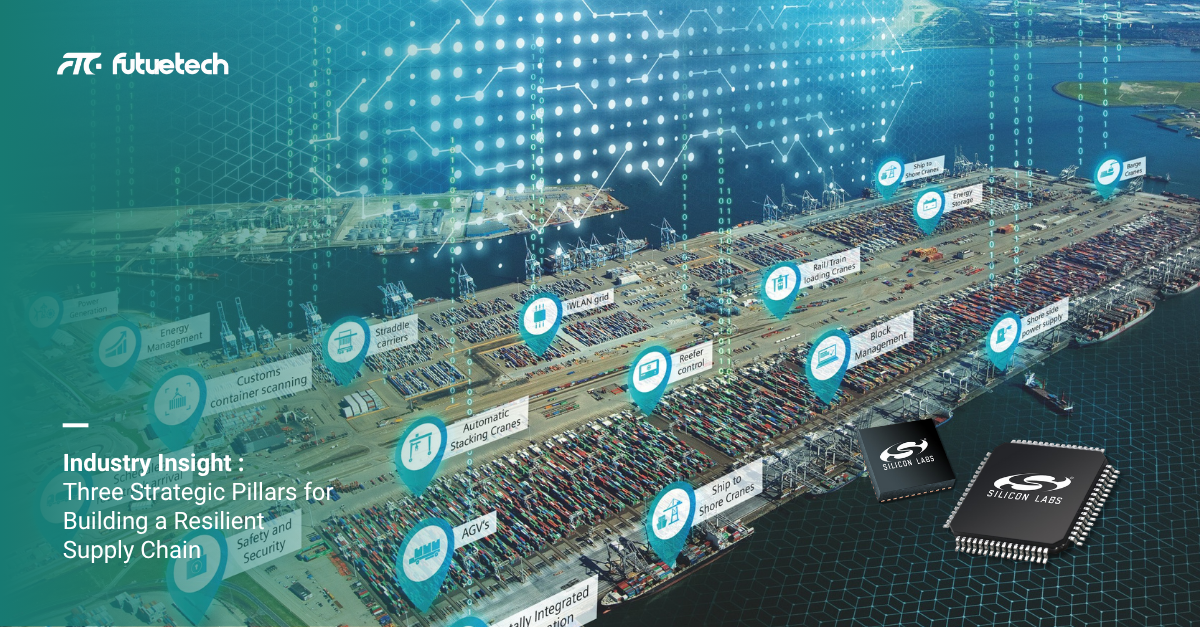

2. Digital Tools: Improving Visibility and Agility

Visibility is a critical enabler of resilience. Without a clear, real-time picture of the entire supply chain—from raw material sourcing to last-mile delivery—organizations struggle to react promptly to disruptions or demand shifts.

Advancements in digital technology are transforming how companies manage this complexity:

Real-Time Tracking: The use of IoT devices and RFID tagging allows firms to monitor shipments and inventory status continuously, reducing blind spots in transit and warehousing.

Predictive Modeling: Data analytics and AI-powered forecasting tools help identify potential risks early—be it material shortages, weather-related delays, or demand spikes—so mitigation plans can be enacted sooner.

Collaborative Platforms: Cloud-based ecosystems enable seamless communication between manufacturers, suppliers, and logistics providers, fostering quicker response and more synchronized decision-making.

Some companies have begun using digital twins, or virtual representations of their supply chain networks, to simulate different disruption scenarios and stress-test their resilience strategies. Others are exploring blockchain-based traceability to improve transparency, especially in high-stakes sectors like pharmaceuticals or food safety.

While the pace of digital transformation varies by industry and region, the shift toward data-informed, agile supply chains is increasingly seen as a long-term necessity—not just a crisis response.

3. Strategic Buffering and Flexible Manufacturing

Complete supply chain optimization can no longer be about reducing inventory to absolute minimums. In the post-pandemic world, strategic stockholding has regained relevance as a form of risk insurance.

Safety Stock for Critical Items: Keeping extra inventory of essential components—such as semiconductors, specialty metals, or specific connectors—can help bridge short-term supply disruptions.

Regional Production Flexibility: Diversifying production capacity across locations allows businesses to reallocate workloads if a specific facility is compromised.

Agile Capacity Models: Some companies have adopted flexible manufacturing or contract production models that can scale up or shift based on real-time demand or supply availability.

This approach not only cushions operational impact during disruptions but also builds the foundation for faster recovery and customer responsiveness. It’s no longer about having the lowest-cost supply chain—it’s about having the most adaptive one.

Equally important is maintaining updated risk assessment frameworks and contingency plans that guide decision-making when things go off-script. Preparedness, rather than prediction alone, often determines the extent of operational continuity.

Looking Ahead: Resilience as a Business Imperative

As the external environment continues to evolve, supply chains must evolve with it. The ability to maintain operational continuity in the face of disruption has become a key competitive differentiator—not just a matter of risk management, but one of strategic advantage.

Diversification, digitization, and strategic buffering are practical, actionable approaches that companies can adopt today. Those who invest in these capabilities will not only protect themselves from future shocks but also position themselves to grow with confidence in a less predictable world.

At Futuretech Components, we understand the critical importance of supply chain resilience—especially in the fast-paced and quality-sensitive world of electronic components. Our global sourcing network, reliable partner ecosystem, and agile response capabilities ensure that our customers stay ahead of disruptions. Whether you're seeking consistent component availability, technical support, or flexible logistics solutions, Futuretech is here to support your supply chain—today and tomorrow.